Customized EV Charging Box Sheet Metal - Charging Station Fabrication With Powder Coated

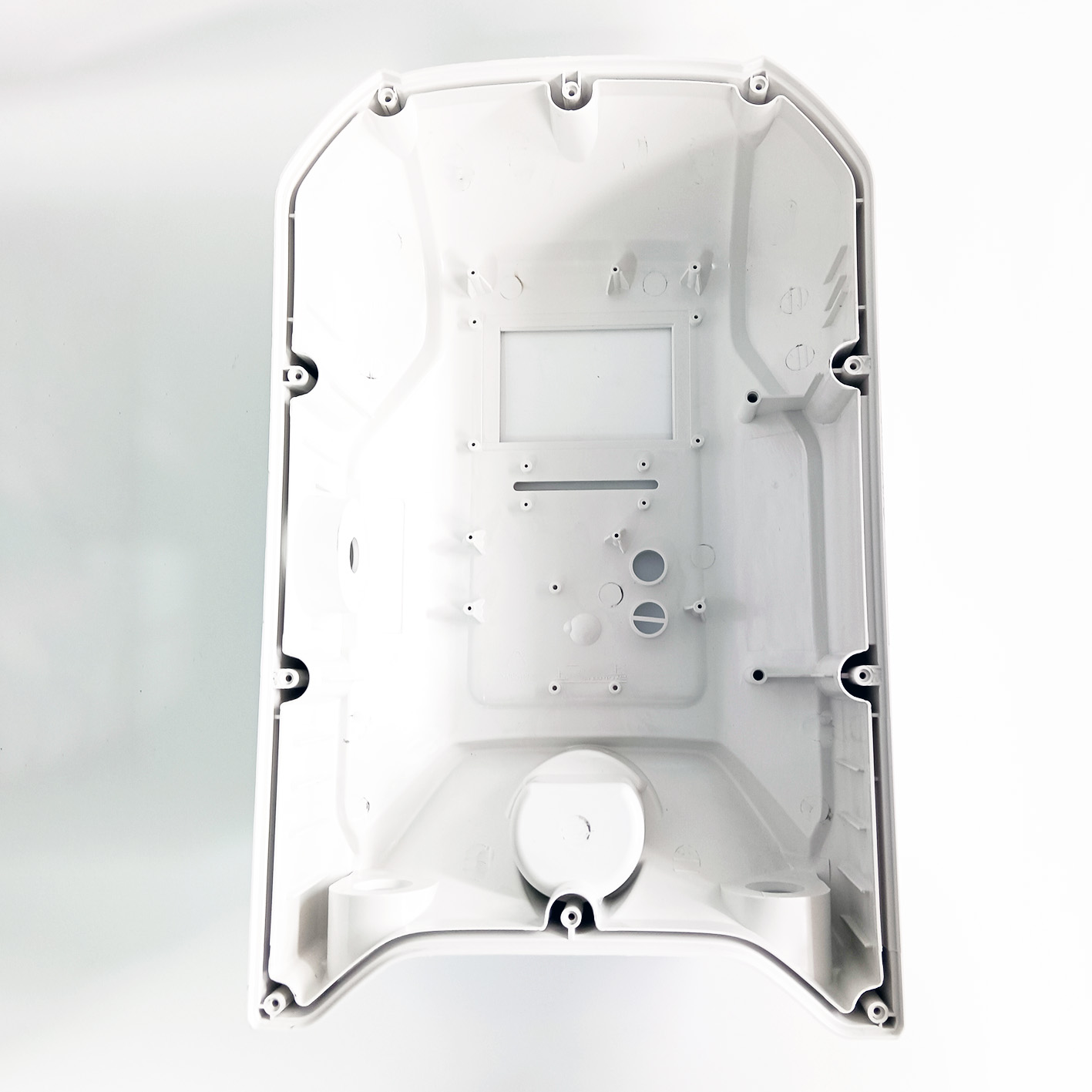

The car charging station is composed of a charging station shell and internal components. The charging station shell is divided into a charging station upper shell and a charging station bottom shell. The upper shell is generally made of injection molded parts, and the lower shell base is made of metal sheet metal. The internal components are installed on the bottom shell of the charging station, so the charging station bottom shell needs a more rigorous structure to support the internal components.

The shell of the charging gun is generally made of halogen-free flame retardant PC/ABS alloy material with good flame retardancy, weather resistance, and low temperature resistance. Due to the majority of outdoor use, it is necessary to withstand wind, rain, high temperature, and cold. In addition to contact with engine oil and gasoline, in addition to mechanical performance and environmental requirements, it is also necessary to fully ensure human contact safety. Therefore, the selection of materials must meet strict requirements such as flame retardancy, weather resistance, low temperature resistance, oil resistance, insulation, and aging resistance.

FUERD has 35 years of experience in automotive parts manufacturing and is a modern manufacturing enterprise specializing in the production of various automotive parts, integrating research and development, design, production, sales, and service. We are closely following the development trend of the new energy vehicle industry, conducting technical reserves in advance in the field of charging pile casings, vigorously developing materials suitable for charging pile casings of new energy vehicles, and continuously providing sorting solutions for charging pile casings of new energy vehicles.

|

|

ABS+PC

|

|

|

Black, white, red, green, transparent or any color according to Pantone code

|

|

|

As per customer's requirements

|

|

|

-20℃~+55℃

|

|

|

Injection molding, CNC machining, Extrusion.

|

|

|

Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide

|

|

|

EV Parts, Automotive, ATV, Mechanical equipment

|

|

|

We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured

|